03 Oct, 2022

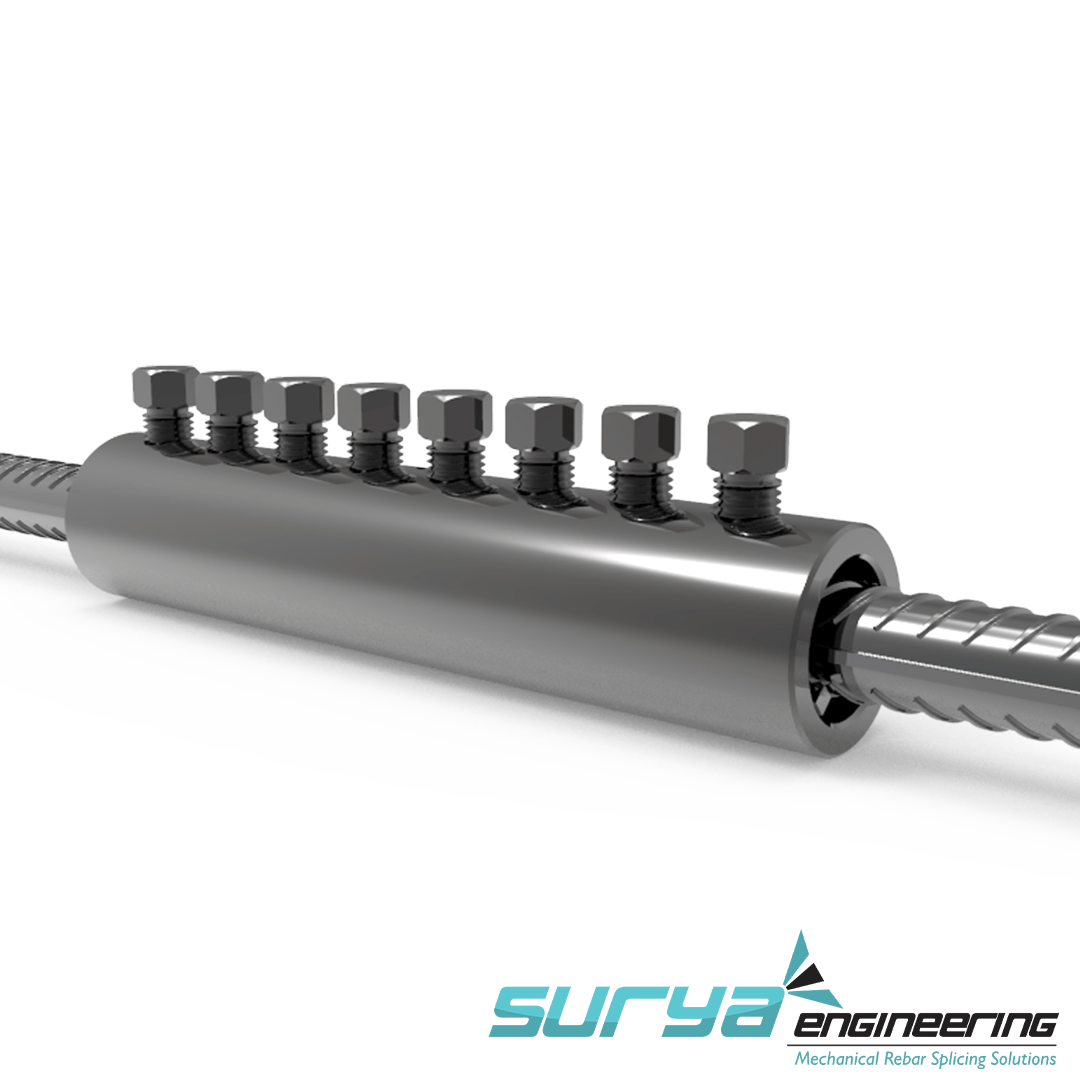

The conventional old method of connecting two reinforcement bars with lap joints continuity in reinforced concrete need not be always appropriate. Advantages of simplicity and economy in lap splicing is limited to smaller diameter bars, mechanical couplers offer the solution for splicing when large-diameter bars are involved like 16, 20, 25 and 32 mm Diameter where huge cost saving can be done.

It's technically Good in Spliced rebar performs like continuous reinforcement System. Splicing develops strength mechanically, independent of concrete. Therefore provides ductility in RCC structures independent condition of the concrete. Proven cyclic performance of spliced rebar offers strength during man-made, seismic, or other natural events.

Rebar coupler reduces rebar congestion and improves concrete flow & consolidation. It offers greater flexibility in design options. The simplicity in detailing of reinforcement, particularly in reinforcement congestion zones minimizes the reinforcement fixing errors, detailing and fixing of seismic reinforcement becomes effortless. Workability with a higher steel-to-concrete ratio allows optimum sizing of the RCC structural column.

Reinforcement coupler offers quality, cost, and time-saving. Fixing couplers requires no special skills or types of equipment. Simple mechanical ways in adopting mechanical splicing compared to lapping accelerate construction schedules for optimum cost and efficiency. Handling the rebar in convenient sizes saves valuable crane time. It is economical to use couplers for higher diameter rebar as it saves on considerable weight and rebar wastage.

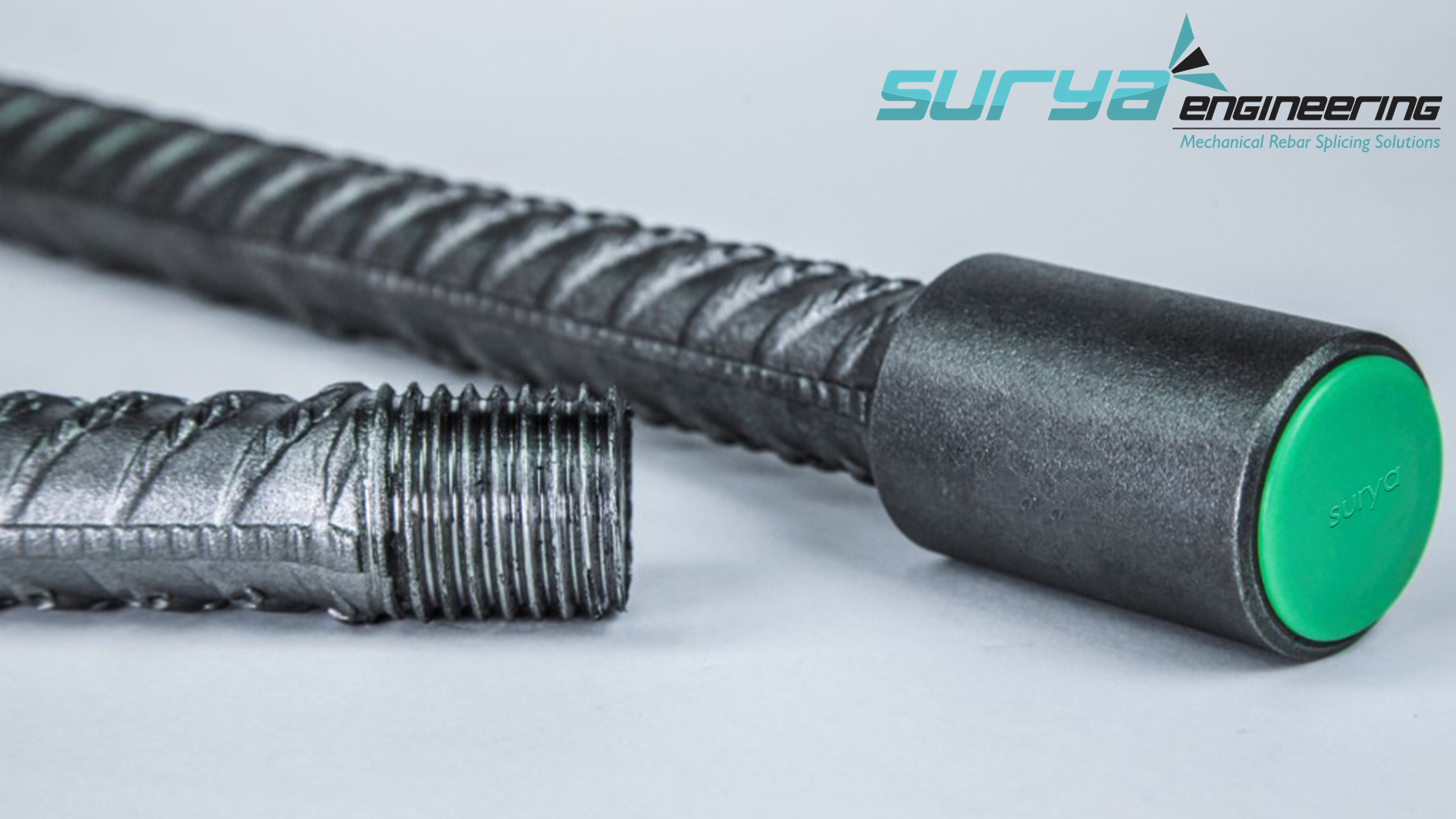

Rebar coupler can be made easily on a CNC Machine, where the loss of cost-saving can be done for large diameters like 16, 20, 32 and 25mm Rebar TMT bars.

EN 8 D Steel Grade is used to manufacture Rebar coupler with a carbon content of 0.40 to 0.45 %. C 454 Grade also can be used to sustain 650 MPA. some time for special purpose chromium carbon is also used for 900 MPA.

Shivam

10 Oct 2022

"

Hello "

LEAVE A COMMENTS

SURYA MBT COUPLER

22 Aug, 2025 - By Surya

Engineering

WHAT KIND OF TESTING IS PERFORMED ON ...

22 Nov, 2024 - By Surya

Engineering

What are the benefits of Rebar Couplers ...

31 Aug, 2023 - By Surya

Engineering