SURYA ENGINEERING is introducing in the market a parallel threaded mechanical splicing system which was formed in the year 2012 by a group of indigenous professionals with over 10 years experience in Construction. In short span of 4-5 years, we have established our name as one of the leading company in Construction field. The company has its own offices in Mumbai & Factory at Sakinaka. We have one of the largest Manufacturer & Supplier network in Maharashtra and in India & having stock & sales. Our customer base varies from Government to public & private sector throughout our country, rendering our Services is the area where lot of importance is given to quality total commitment to customer’s satisfaction is utmost objectives to all the persons and is always given attention to priority. Our sales service is to support function to sales & to provide consistent quality of parallel threaded mechanical splices where threading is one of the most important system & we never compromising with our quality system according to the requirement of our valued customer/clients.

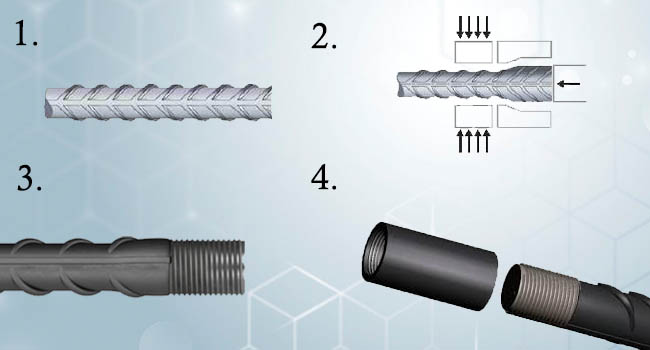

As SURYA ENGINEERING is in the market of a parallel threaded mechanical splicing system designed for the connection of concrete reinforcing bars of 16mm to 56 mm manufactured adopting international quality conforming to British & American standard BS 8110 (1997) & ACI 318 (2005), ACI 349, ASME Sec III, Div 2 by manufacturing in A3 steps like cutting, cold forging & Threading having wide spread benefits easy installation with no torque wrenching required & with numerical control (CNC) for making couplers. The mechanical splice connection develops in tension or compression more than 125% of the specified yield strength of the concrete reinforcement bar. The connection designed under strict quality assurance by the ACP to withstand minimum breaking strength of 650 N/MM2.Thus the Mechanical splicing systems is the most reliable, economical & having additional advantages & have been designed friendly with assurance of maintaining load path in continuity of the structural reinforcement, independent of the conditions or the existence of the concrete. The SURYA ENGINEERING is also manufacturing Bar Break (BB) Type 2 cold forged parallel Threaded Mechanical Coupler as per Seismic Design ACI-318 on client’s Specific order.

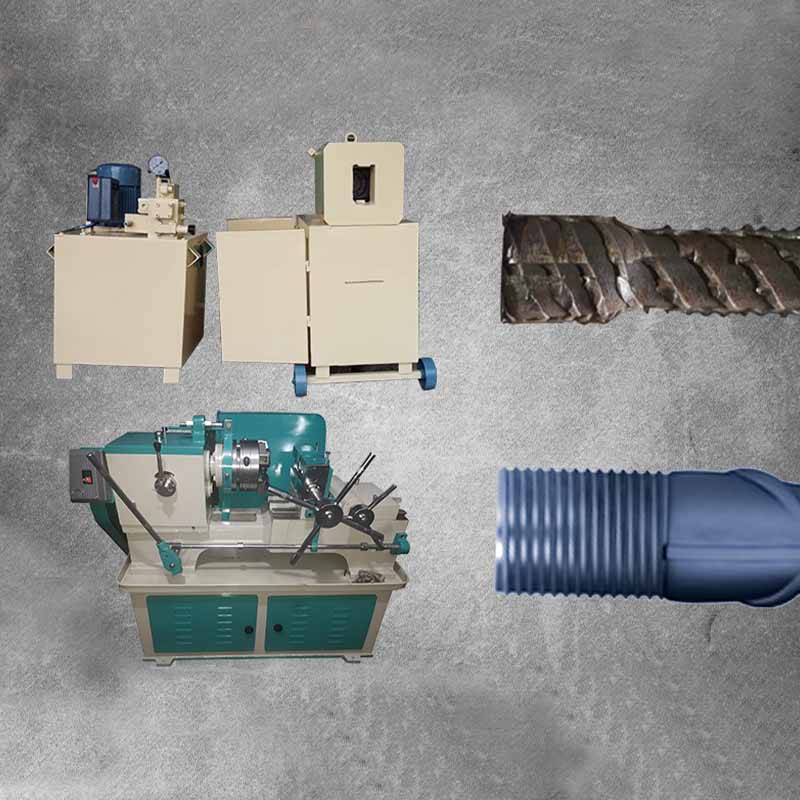

Cutting The end of the reinforcing bar is sawn square.

Cold Forging The sawn end of the reinforcing bar is then enlarged by a patented cold forging process. The core diameter of the bar is increased to a pre-determined diameter.

Turning The rib of forged bar is removed by turning process for even surface.

Threading Finally, the thread is mechanically cut onto the enlarged end of the bar.

Steel EN 8D or C-45 steel purchased by ISMT are tested. Once the material is received from the supplier inspection is carriedout as per the raw material quality plan. Raw materials are tested at regular intervals as per the requirements of customer. The raw material is tested to check the chemical compositions.

Each lot of raw material is given a unqiue batch code starting with serial number and is sent for chemical compositions. Once the material is found OK as per the requirements, the QC in charge signs in the party’s challan and sends the party challan with one copy of inspection report to head office.

TMT Threading production at site are carried out under controlled conditions to ensure compliance of product to specified requirements & Customer Requirements. Site incharge and Production Supervisor, Responsible for monitorni g process parameters, operators and maintaining related production records.

To provide guidelines for measuring and monitoring of product parameters for verifying conformance to specified requirements. QC- In charge is responsible for implementation of this procedure. Production planning is based on the requirements given by the customer thru work order. The Site in charge plans the production of threading.